There are a number of options for subgrades that are weak and that cannot be strengthened by drying and compaction:

- Excavation of the unsuitable material to a depth, typically 0.5 m or more below the formation surface, disposing of this in a suitable fill area off the road formation, and importing alternative suitable formation material to replace the reject material

- Mixing additional material with the unsuitable subgrade material to improve its consistency and strength. This is referred to as mechanical stabilisation

- Mixing in lime or cement stabilisation. This is referred to as chemical stabilisation

- Installing geosynthetic materials over the weak areas prior to or during placement of the pavement layers.

6.8.1 Corduroy

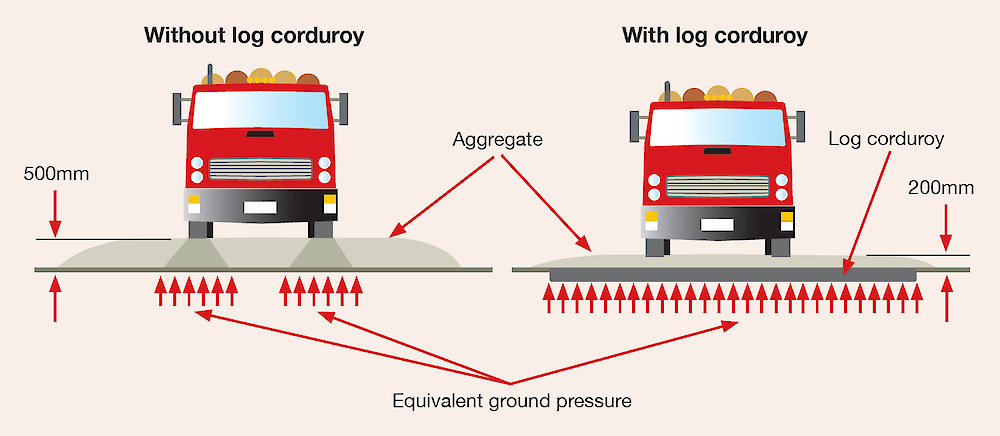

Effect of log corduroy reinforcement

Slash corduroy provided truck access on a step section of road after the subgrade failedCorduroy is a valuable stabilisation alternative to geosynthetics, stabilisation chemicals and other products for forestry roads. Corduroy involves laying a mat of slash or logs on top of the subgrade. Aggregate is applied on top. To lay it requires considerable machine and labour time, and often uses wood that could otherwise be sold. However, corduroy may be the only cost-effective option for constructing roads over very weak and wet subgrades.

Slash corduroy provided truck access on a step section of road after the subgrade failedCorduroy is a valuable stabilisation alternative to geosynthetics, stabilisation chemicals and other products for forestry roads. Corduroy involves laying a mat of slash or logs on top of the subgrade. Aggregate is applied on top. To lay it requires considerable machine and labour time, and often uses wood that could otherwise be sold. However, corduroy may be the only cost-effective option for constructing roads over very weak and wet subgrades.

Using corduroy for forestry road or landing construction:

- Enables construction over very weak subgrades

- Has the potential to reduce the quantity of expensive aggregate required

- Allows the road to be used immediately after construction

- Minimises exposed earth that could erode (often when built on top of existing vegetation)

- Allows aggregate and corduroy to be recovered from roads that have been abandoned

- Provides a separation layer and improves drainage.

The major advantage of using corduroy is that it acts as a separator and a re-enforcer. The slash or logs separate a weak subgrade from the aggregate. This reduces any intermixing of the two, and ensures that the load bearing functions of the base course are performed without contamination from the weaker subgrade. When aggregate comes into contact with the weak subgrade, it becomes slippery, which reduces the particle interlock (bearing capacity). Consequently, the road may fail.

The effect of corduroy laid across the subgrade is to spread the load. The load is redistributed over the whole width of the corduroy, effectively increasing its load bearing area. Reinforcement is greater with log than with slash corduroy since the logs act as a rigid platform.

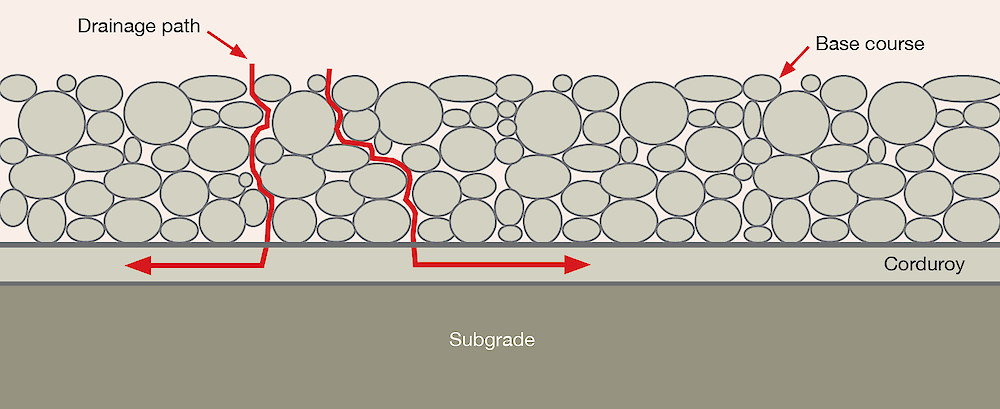

Corduroy can improve drainage by providing a permeable layer between the base course and the subgrade. Water on the road surface percolates through the base course, and then flows along the corduroy plane, as shown below.

Flow of water along the corduroy plane

6.8.2 Geosynthetics and geogrids

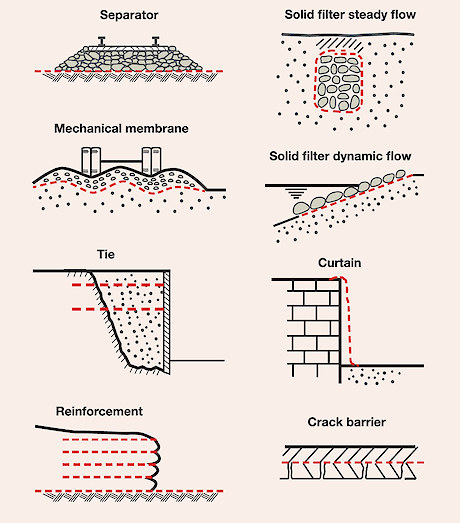

Uses for geosynthetics Source: Douglas A. Roadnotes Vol. 2 No. 8

Source: Douglas A. Roadnotes Vol. 2 No. 8 Geosynthetic cloth being used as a separation layer

Geosynthetic cloth being used as a separation layer Geogrid laid on a subgrade prior to application of the aggregate layerThe two main types of geosynthetics that may be used for forest roads are geosynthetic cloth and geogrids. These products have multiple uses, but they are most often used on roads with weak subgrades. They are an alternative to corduroying. Only use geosynthetics when a lower cost, equally effective method cannot be used or when a long-lasting solution is required. For example, a layer of corduroy may solve a subgrade stabilisation problem more economically than a geosynthetic; however, corduroy will decompose over time, and would be inappropriate for an important secondary or arterial road.

Geogrid laid on a subgrade prior to application of the aggregate layerThe two main types of geosynthetics that may be used for forest roads are geosynthetic cloth and geogrids. These products have multiple uses, but they are most often used on roads with weak subgrades. They are an alternative to corduroying. Only use geosynthetics when a lower cost, equally effective method cannot be used or when a long-lasting solution is required. For example, a layer of corduroy may solve a subgrade stabilisation problem more economically than a geosynthetic; however, corduroy will decompose over time, and would be inappropriate for an important secondary or arterial road.

Geosynthetic cloth and geogrid work in different ways. Geosynthetic cloth provides a separation layer between the pavement and soft subgrade materials. This prevents fines from migrating and contaminating the pavement layer. Effective separation maintains aggregate layer strength and enables aggregate to be recovered for later re-use.

Geogrids are grids of high strength plastic that are laid between the subgrade and aggregate layers. The mesh interlocks with the aggregate to improve the shear strength of the aggregate layer.

The main benefit of these products is that they can significantly reduce the required thickness of pavement (up to 40% in some studies), and can allow roads to be constructed on weak subgrade that would be otherwise unsuitable for construction. A cost-benefit analysis may be used to determine whether geosynthetic cloth or geogrids (or a combination of both) is suitable for a given road. Geosynthetic cloth and geogrids are non-biodegradable, so are well suited for roads that will be used for extended periods of time. Geosynthetic cloth and geogrids may be used in combination, with the grid overlying the cloth, for construction on particularly weak subgrade.

Geosynthetics can also be used as a drainage filter, restricting water movements into the subgrade or pavement. They also stop the migration of fine soil particles from aggregate material while under pressure from water. For example, a geosynthetic wrapped around coarse gravel that fills a drainage trench, allows water to pass across the soil/fabric interface while retaining soil particles. Some non-woven geosynthetics are quite thick and can pass water along their length as well as across their thickness. This improves drainage of excess water pressure in the soil.

Geosynthetic cloth and geogrids are relatively easy to use; however, correct application often requires specialised design input to determine the best technique, location and pavement design. Road planners should seek specialist advice prior to using these products.