Compaction is an important task in building a road and landing. How you compact depends on what material you are working in. All compaction needs moisture, but not too much or too little.

Why compact?

- Compaction strengthens the fill and the road. It reduces the risk of fill movement or settlement on steep or unstable slopes

- It reduces the amount of road metal needed as road subgrade is stronger

- It helps protect or ‘seal off’ earthworks from water penetration

- It can reduce repair and maintenance costs

Which compactor for the job?

Step 1: Is the soil a clay – try to roll a worm!

- Moisten the soil and try and roll it into a thin worm 3-5 mm thick

- If the soil feels sticky and turns into a snake without cracking, you have clay

- A clay with sand – you will feel the sand particles

Step 2: Is the soil silty – try the tap test!

- Roll a wet soil sample into a 20 mm ball and flatten it

- Now tap the hand to see if water arises. If so, it is a silt

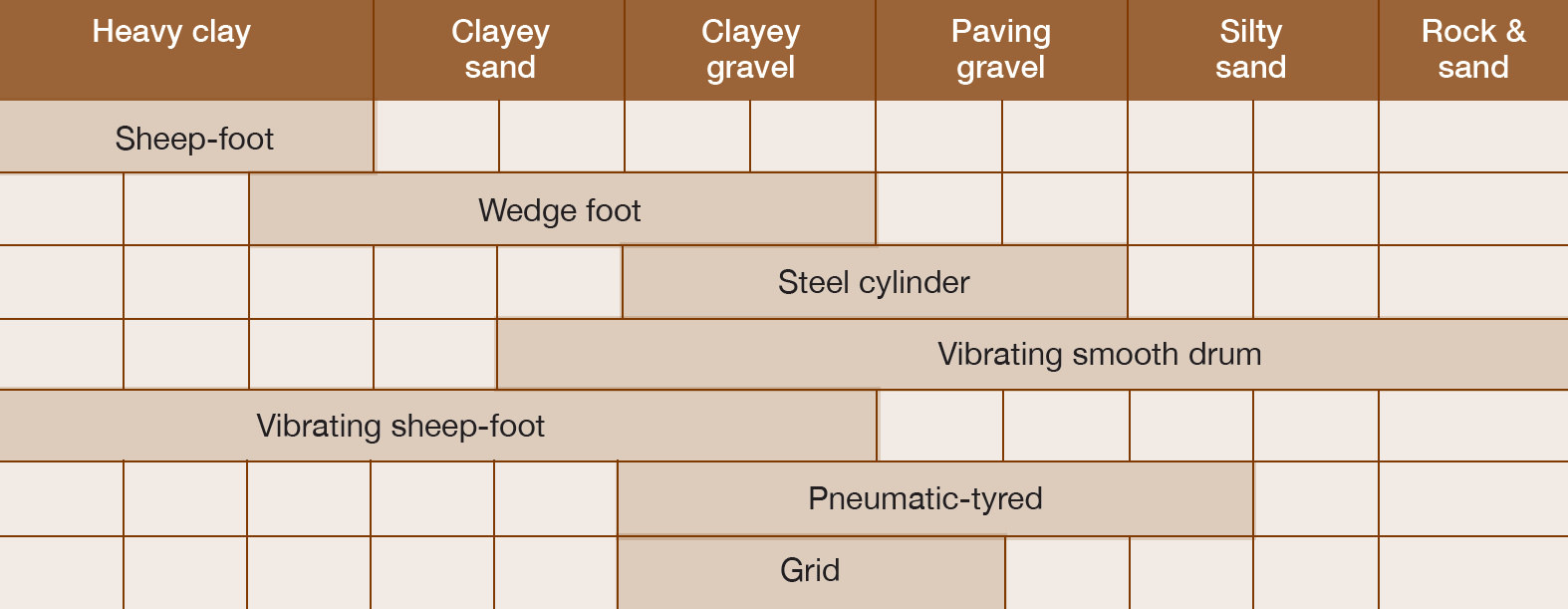

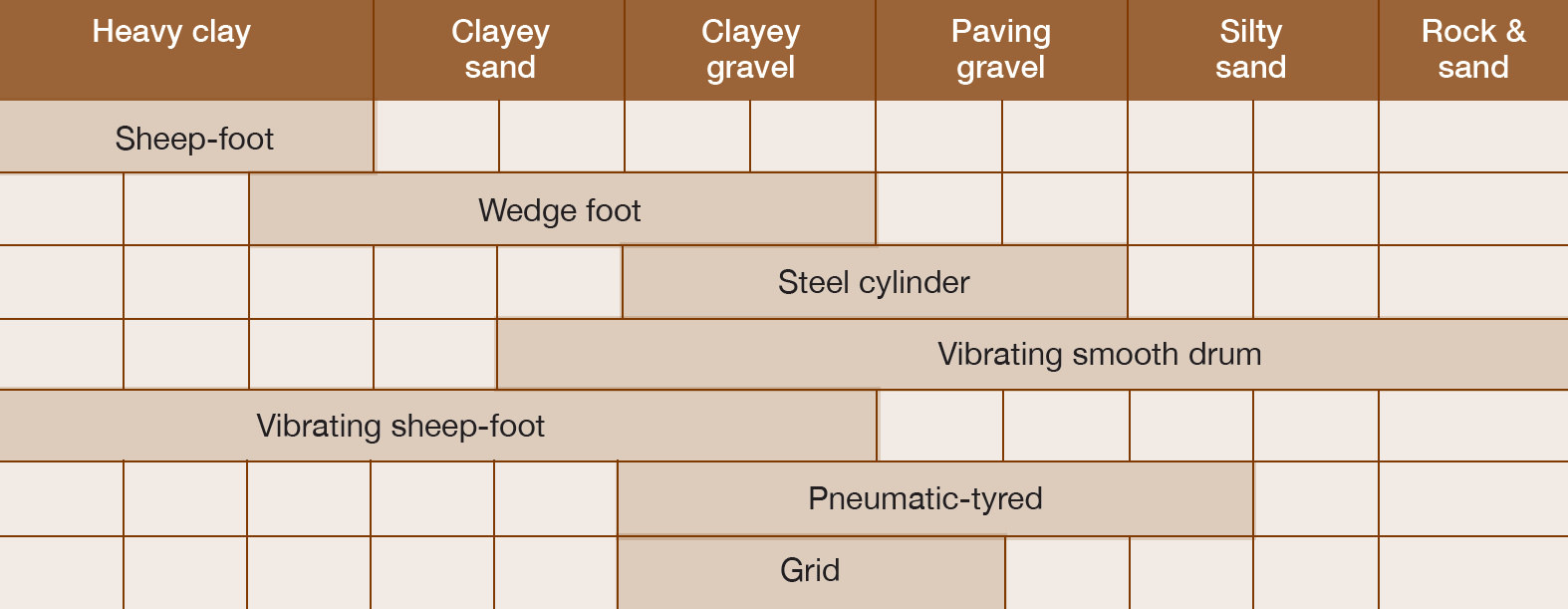

Table 5: Compactor and soil type

Step 3: Look at the table above

- Sheep or wedge foot rollers are the most useful in formation

- Vibrating drum rollers (smooth) are useful for sealing aggregate

- Heavy compactors work better

- Loaded metal truck wheels compact

How much moisture is enough?

Step 1: Do the squeeze test

- Squeeze some material in your hand, then take off the pressure

- If it just holds together, and the content doesn’t stick to your fingers, the moisture is about right

- More granular materials are less likely to hold too much water

Step 2: Plan your next steps

Table 6: Earthworks compaction

How thick can a layer be compacted?

Limit layer thickness, so compaction goes the full depth of each layer.

Table 7: Earthworks compaction

- The correct compactor − a vibrating sheep-foot − has been used

- The right moisture content ensured good compaction

- Compaction had been done in the right layer thickness for the material

- The material has not been over-compacted

- Dozers and excavators are not compactors

- Wide tracked machines apply low ground pressure even though they are heavy

- Track rolling only gives minor compaction, however, it tightens the fill by breaking down larger material

- The metal is being compacted with the correct compactor − a vibrating steel drum

- The aggregate is compacted in layers less than 150 mm

- Excessive vibrating rolling has brought moisture to the surface and hasn’t improved the result

- Do not try to compact wet or very dry materials, as these may become liquid

- Penetrometers are useful for identifying subgrade weaknesses

- They also show that the subgrade has met compaction standards

- Lack of compaction, or too much moisture in the fill, led to this major road failure

- Water will enter the tension cracks and make the fill even less stable